Cottees' 1987 Sigma GN GSR Super Edition

Re: Cottees' Sigma GN Build

The hand brake needs tightening I'd say.Main reason for the bricks is that I haven't adjusted the shifter yet. So P = Reverse, R = Reverse, N = Reverse, D = Drive.

Re: Cottees' Sigma GN Build

These are the wheels I want to get for the Sigma if I can't find a set of Simmons B45s. I think that Performance Wheels might no longer be making wheels like Simmons.

http://www.allwheels.com.au/cata/produc ... 428&page=1

http://www.performancewheels.com.au/all ... lassic.asp

There is also these, but they only go up to 14":

http://www.bobjane.com.au/wheelset-deta ... a4j7nuj0a5

I originally wanted something like this on my first Sigma, in 15"-16", but I am now wanting something that is more classic looking.

http://www.bobjane.com.au/wheelset-deta ... a4j7nuj0a5

This website also sells new and used wheels, so something that I am looking for might come up.

http://www.otomoto.com.au/showroom.htm

http://www.allwheels.com.au/cata/produc ... 428&page=1

http://www.performancewheels.com.au/all ... lassic.asp

There is also these, but they only go up to 14":

http://www.bobjane.com.au/wheelset-deta ... a4j7nuj0a5

I originally wanted something like this on my first Sigma, in 15"-16", but I am now wanting something that is more classic looking.

http://www.bobjane.com.au/wheelset-deta ... a4j7nuj0a5

This website also sells new and used wheels, so something that I am looking for might come up.

http://www.otomoto.com.au/showroom.htm

Re: Cottees' Sigma GN Build

Removed the rear struts. Left the handbrake cables attached.

Oops... Those bolts are a little tight.

Got the IRS from out of under the car.

Can see that the diff centre is open, not LSD. I knew this when I saw the option codes on the plates on the firewall, but now it is confirmed. Still will be useful to do some measuring to compare it to the Scorpion diff centre.

Comparing the Starion Master Cylinder with one from my Sigma and a 1" Master Cylinder from a Commodore.

Also found some more damage on the Starion.

Oops... Those bolts are a little tight.

Got the IRS from out of under the car.

Can see that the diff centre is open, not LSD. I knew this when I saw the option codes on the plates on the firewall, but now it is confirmed. Still will be useful to do some measuring to compare it to the Scorpion diff centre.

Comparing the Starion Master Cylinder with one from my Sigma and a 1" Master Cylinder from a Commodore.

Also found some more damage on the Starion.

Re: Cottees' Sigma GN Build

wow how old was the spanner?

but even still holy crap hahaha

but even still holy crap hahaha

TVMDouble0h!Sixx

1985 GK GSR

1985 GK GSR

Re: Cottees' Sigma GN Build

It would have been only a couple years old. When ever I come across a bolt that is a little tight, I put the ring end of another spanner onto the open end of the spanner I am using, and use it as extra leverage. All other times it has worked ok, until today.TVM006 wrote:wow how old was the spanner?

but even still holy crap hahaha

Re: Cottees' Sigma GN Build

haha no good.. yeh i use the same technique as you!

TVMDouble0h!Sixx

1985 GK GSR

1985 GK GSR

Re: Cottees' Sigma GN Build

This should be the last lot of pics of the Starion. I have taken off all the parts I needed plus a whole heap that might come in handy later. Now it is just a matter of getting it on a trailer and scrapping it.

Some more rust I found.

The damage to the front passenger side of the car. Under the popup headlight, the motor to raise and lower the light had snapped in half.

There was even plants starting to grow in the carpet.

Some more rust I found.

The damage to the front passenger side of the car. Under the popup headlight, the motor to raise and lower the light had snapped in half.

There was even plants starting to grow in the carpet.

Re: Cottees' Sigma GN Build

I swear, when I get this Sigma running, I'll have no hair left. Either from pulling it out, or from old age. I had some time before work so I thought I'd swap distributors over and see if that makes a difference. There is a known working distributor on the Magna engine I have spare, so that one should be good for testing. tried to take it out, but the damn thing was stuck. I was able to pry it out a little way, then it snapped.

It snapped where the o-ring is. Now it is stuck where it is, wont budge at all. I ended up trying to start the Sigma anyway, and the ECU finally threw a proper error code of 22. 22 is Crank Angle Circuit. I have now taken the Distributor out of the Sigma, and will pull it apart and take a closer look when I don't feel like scrapping it again. I can still use some internal parts from the broken distributor, but wont be able to use the entire thing.

It snapped where the o-ring is. Now it is stuck where it is, wont budge at all. I ended up trying to start the Sigma anyway, and the ECU finally threw a proper error code of 22. 22 is Crank Angle Circuit. I have now taken the Distributor out of the Sigma, and will pull it apart and take a closer look when I don't feel like scrapping it again. I can still use some internal parts from the broken distributor, but wont be able to use the entire thing.

-

13bsigma

- Posts: 786

- Joined: Sat Sep 26, 2009 10:06 am

- Location: Berowra or gold coast or driving between

Re: Cottees' Sigma GN Build

sounds like a nightmare buddy!!! can i ask why you dont go an after market ECU? even a cheapy to get it running like a microtech digi? they go for around $300. i have 3 of them lol. . thats what i use every time i EFI my 4G5?s. thats what jet is running with 18PSI for T04 boost. . no probs. a bit rough, but it does the job for very little money

1978 GE sigma 57,000kms the toy called silvia. comming to the Gold Coast soon.

1978 GE sigma 87,000kms spare parts for the toy

1996 suzuki baleno turbo. $32,000 invested in it. $22,000 in the engine. $10,000 in sound

1996 suzuki baleno GTX. getting shaved and resprayed soon and receiving turbo engine

1980 GH sigma AKA JET.51G 18 PSI of T04 injected power.

1978 GE sigma 87,000kms spare parts for the toy

1996 suzuki baleno turbo. $32,000 invested in it. $22,000 in the engine. $10,000 in sound

1996 suzuki baleno GTX. getting shaved and resprayed soon and receiving turbo engine

1980 GH sigma AKA JET.51G 18 PSI of T04 injected power.

Re: Cottees' Sigma GN Build

I do plan on going aftermarket ECU, but closer to when I am going Turbo. Still looking at a Megasquirt. I just need the time to sit down and work out all the bugs. Hopefully 4 weeks annual leave is enough time.

-

13bsigma

- Posts: 786

- Joined: Sat Sep 26, 2009 10:06 am

- Location: Berowra or gold coast or driving between

Re: Cottees' Sigma GN Build

your very committed lol. . i'll give you that ;D

1978 GE sigma 57,000kms the toy called silvia. comming to the Gold Coast soon.

1978 GE sigma 87,000kms spare parts for the toy

1996 suzuki baleno turbo. $32,000 invested in it. $22,000 in the engine. $10,000 in sound

1996 suzuki baleno GTX. getting shaved and resprayed soon and receiving turbo engine

1980 GH sigma AKA JET.51G 18 PSI of T04 injected power.

1978 GE sigma 87,000kms spare parts for the toy

1996 suzuki baleno turbo. $32,000 invested in it. $22,000 in the engine. $10,000 in sound

1996 suzuki baleno GTX. getting shaved and resprayed soon and receiving turbo engine

1980 GH sigma AKA JET.51G 18 PSI of T04 injected power.

Re: Cottees' Sigma GN Build

Maybe this is a dumb question but why would you pry a alloy housing that is in a interferance fit hole?

You needed to rotate the housing as you pull. the tension on the oil will make it appear stuck. The rotor inside will also rotate as the teeth run through the gear set infront of the top timing chain sprocket.

A less Heath Robinson approach might save you some frustration and dollars.

What is wrong with you current distributor?

Cheers

You needed to rotate the housing as you pull. the tension on the oil will make it appear stuck. The rotor inside will also rotate as the teeth run through the gear set infront of the top timing chain sprocket.

A less Heath Robinson approach might save you some frustration and dollars.

What is wrong with you current distributor?

Cheers

The way God intended it.....Chrysler for the win

Re: Cottees' Sigma GN Build

ther not a interferance fit

thay have .12 clearance and a o,ring to seal

mystery is why is it stuck

cheers stealth

thay have .12 clearance and a o,ring to seal

mystery is why is it stuck

cheers stealth

Engineering the unfair advantage !

Red bull , fuelling the fastest race cars on earth !

Red bull , fuelling the fastest race cars on earth !

-

Superscan811

- Posts: 1689

- Joined: Sun Mar 22, 2009 4:12 pm

- Location: Sydney

Re: Cottees' Sigma GN Build

Magna's tend to cook the oil. The reason it was stuck is because of the burnt oil stuck to the housing.Cottees wrote:tried to take it out, but the damn thing was stuck.

Correct, but a better way, if you aren't going to to be using this engine, is to use some emery cloth or similar to remove the burnt oil deposits.oldn64 wrote:You needed to rotate the housing as you pull.

Cheers.

Re: Cottees' Sigma GN Build

stealth wrote:ther not a interferance fit

thay have .12 clearance and a o,ring to seal

mystery is why is it stuck

cheers stealth

Gee I am sorry that I did not use the finite measurements. I was trying to get a point across in the simplest easiest way. I did notice that you didnt supply a measure so I am guess that 0.12 is still bloody small... :S

Secondly I have seen many stuck dizzys for a number of reasons, one was due to areldite holding the housing in but I seriously doubt this to be the case. I also doubt that most people would not pry a dizzy off a alloy head and alloy housing?

Teach a man to fish and he will feed himself for years, give a man a fish and he will starve in 7.

Cheers

The way God intended it.....Chrysler for the win

Re: Cottees' Sigma GN Build

oldn64 wrote:Maybe this is a dumb question but why would you pry a alloy housing that is in a interferance fit hole?

I have taken the dizzy out of my Sigma many times, and it just slips out. On the spare Magna engine, undone the bolt, and tried to twist and pull. It would not even twist. I tapped it with the hammer, and it would twist very little.oldn64 wrote:You needed to rotate the housing as you pull.

I think the angle sensor in it is dodgy.oldn64 wrote:What is wrong with you current distributor?

The part of the dizzy that was in the head was black, and as I was tapping and prying it out, the black of the shaft was starting to come off. That would explain why it was having trouble coming out, but not twisting when I hadn't even started pulling yet.Superscan811 wrote:Magna's tend to cook the oil. The reason it was stuck is because of the burnt oil stuck to the housing.

I undone the bolt, any began to try and get it out when the rocker cover was still on. When it wouldn't budge, I took the rocker cover off to see if something was stopping it form coming out. The centre shaft had slight movement, so that hadn't seized and was stopping it.oldn64 wrote:The rotor inside will also rotate as the teeth run through the gear set infront of the top timing chain sprocket.

Engine make me angry. Big hammer good!oldn64 wrote:A less Heath Robinson approach might save you some frustration and dollars.

Where the dizzy is in the photo, it is stuck in that position. It wont come out, and wont go back in. Even with some encouragement with a hammer, it just wont budge. I'll just dismantle the dizzy where it is, then try and get the rest out when I have time.

Re: Cottees' Sigma GN Build

I just googled what 'Heath Robinson' was.

http://en.wikipedia.org/wiki/W._Heath_Robinson

It isn't that complex. It is pretty much just a stock Magna setup, but in the Sigma.

http://en.wikipedia.org/wiki/W._Heath_Robinson

It isn't that complex. It is pretty much just a stock Magna setup, but in the Sigma.

Re: Cottees' Sigma GN Build

As Stealth stated why was it stuck, if something does not move investigation should be done. There is a reason for it not moving you will need to find it. All dizzys that I have pulled have not been sloppy nor loose, they did require twisting and movement to pull out.Cottees wrote:oldn64 wrote:Maybe this is a dumb question but why would you pry a alloy housing that is in a interferance fit hole?I have taken the dizzy out of my Sigma many times, and it just slips out. On the spare Magna engine, undone the bolt, and tried to twist and pull. It would not even twist. I tapped it with the hammer, and it would twist very little.oldn64 wrote:You needed to rotate the housing as you pull.

Have a read of a manual and follow the testing proceedure to know whether it is faulty or not. You should be able to determine the condition of the current dizzy.Cottees wrote:I think the angle sensor in it is dodgy.oldn64 wrote:What is wrong with you current distributor?

See what you mean, you now have a broken dizzy so the bigger hammer worked a treat hey... :S I was taught early on that looking at why something was not disassembling was better than a bigger hammer. A mate repairs brass intruments (things like trumpets and trumbones etc) The hammers he uses are almost doll size, bigger hammers would not work and would be bad, bigger does not always mean better. You first problem was that the engine made you angry. At this point you should walk away, have a cuppa and return to it after either a read or thought process of what could possibily be the cause. Then with a plan of attack look for the problem and then use a solution. 99% of the time if you first reaction is bigger hammer then you will find that it will end in tears.Cottees wrote:Engine make me angry. Big hammer good!oldn64 wrote:A less Heath Robinson approach might save you some frustration and dollars.

You have broken the dizzy and I would expect peened one of the end over so the shaft is not bent but has the characteristic of being bent, there is no way in hell it will move now. You would need to fix the "bend" first then it will move back in. Hammer in this instance would be bad. I would be cutting the o ring first and assessing what is stopping it this side. Secondly By hiting it is this broken state you will find that the impact shock will be at an angle and not directly down the shaft, I am not sure it woul doi you any good and you risk cracking the head or seizing the dizzy in the for good.Cottees wrote:Where the dizzy is in the photo, it is stuck in that position. It wont come out, and wont go back in. Even with some encouragement with a hammer, it just wont budge. I'll just dismantle the dizzy where it is, then try and get the rest out when I have time.

To dismantle as it sits you are going to need to remove the bolt and mesh gear from the front of teh top timing sprocket. This is not going to be easy and with the dizzy broken like it is the shaft may not turn now. Once this is off you wil then need to remove the roll pin holding the dizzy ger onto the shaft. then remove the gear, again the shaft may be bent now so removing this through the top of the dizzy will be fun. Do to this you will need to disassemble the internals of the dizzy and then it should pull out. Good luck with it but I would find out what is wrong with you old one. If it is like all others I have seen the module under the tin mounted on the dizzy is shot. $50 for a new one and away you go. Do not touch the white paste it is dangerous to you health and if you do then wash your hands. If using a second hand one, go to jaycar or a good electronics shop (stay away from dick smiths or tandy) and get some heat tranfer paste. (this is the white stuff and will help the module survive many years of motoring. One thing to point out is that the screws holding the tinware on are earth point and should be free from dirt and grease. Clean the tinware and the base thoroughly this will ensure a good connection and one thing I would do on your original before replacing anything.

Cheers

The way God intended it.....Chrysler for the win

Re: Cottees' Sigma GN Build

sorry i wasnt getting into you thereoldn64 wrote:stealth wrote:ther not a interferance fit

thay have .12 clearance and a o,ring to seal

mystery is why is it stuck

cheers stealth

Gee I am sorry that I did not use the finite measurements. I was trying to get a point across in the simplest easiest way. I did notice that you didnt supply a measure so I am guess that 0.12 is still bloody small... :S

Secondly I have seen many stuck dizzys for a number of reasons, one was due to areldite holding the housing in but I seriously doubt this to be the case. I also doubt that most people would not pry a dizzy off a alloy head and alloy housing?

Teach a man to fish and he will feed himself for years, give a man a fish and he will starve in 7.

Cheers

just pointing out that there "loose in the hole" .12mm which is just over 4 1/2 thou its not huge but enough to be loose and the o'ring seal

next time i will keep quite ,sorry

cheers stealth

Engineering the unfair advantage !

Red bull , fuelling the fastest race cars on earth !

Red bull , fuelling the fastest race cars on earth !

Re: Cottees' Sigma GN Build

Give a man a fish and he will expect handouts, teach a man to fish and you have your first employee.oldn64 wrote:

Teach a man to fish and he will feed himself for years, give a man a fish and he will starve in 7.

Cheers

Re: Cottees' Sigma GN Build

No No dont stress, hard day at work + OH&S issue with one of my workers + being told I didnt describe something right = taken in wrong light and thinking you are criticising me for not being an english scholar...stealth wrote:sorry i wasnt getting into you there

just pointing out that there "loose in the hole" .12mm which is just over 4 1/2 thou its not huge but enough to be loose and the o'ring seal

next time i will keep quite ,sorry

cheers stealth

I am an Engineer not a English scholar....

all good...

Cheers

The way God intended it.....Chrysler for the win

Re: Cottees' Sigma GN Build

Every other time I have done it, it has slipped in and out nicely. A couple times it needed a slight twist, but it then came out freely. It has always also been a nice fit. When it wasn't budging, I did take the rocker cover off to see why it would be stuck. I didn't see anything obvious. I also thought that using a screw driver to lever it out, it might get past the part that is stuck, and then would come out.oldn64 wrote: As Stealth stated why was it stuck, if something does not move investigation should be done. There is a reason for it not moving you will need to find it. All dizzys that I have pulled have not been sloppy nor loose, they did require twisting and movement to pull out.

The shaft in the middle of the dizzy is not bent, it still has movement.oldn64 wrote:You have broken the dizzy and I would expect peened one of the end over so the shaft is not bent but has the characteristic of being bent, there is no way in hell it will move now.

Re: Cottees' Sigma GN Build

It is finally a sunny day, and I have no work, so I went out and did some testing of the loom etc.

On the way out, I went past the Starion. I left my tool box next to it and thought that the tool box would have been ok in the rain since I closed the top of it. I was sorely wrong.

Anyway, back to the Sigma. Tested out every wire of the Magna loom to make sure nothing was broken. Around half way though, I discovered this :

Could be the cause of some problems. I finished up the testing of the loom, everything was ok. Then fixed the injector plug and double checked it's connection, and all was good. I then moved on to the power supply to the Magna loom, that seemed ok till I tested the power from the 'Starter Circuit'. That was putting out 5v. The car is now kicking over, but spluttering and cutting out, but it is 'progress'. I had to stop testing since the battery was getting pretty low. Now while that is on charge, I am going to play with the new Arduino that just arrived in the mail.

On the way out, I went past the Starion. I left my tool box next to it and thought that the tool box would have been ok in the rain since I closed the top of it. I was sorely wrong.

Anyway, back to the Sigma. Tested out every wire of the Magna loom to make sure nothing was broken. Around half way though, I discovered this :

Could be the cause of some problems. I finished up the testing of the loom, everything was ok. Then fixed the injector plug and double checked it's connection, and all was good. I then moved on to the power supply to the Magna loom, that seemed ok till I tested the power from the 'Starter Circuit'. That was putting out 5v. The car is now kicking over, but spluttering and cutting out, but it is 'progress'. I had to stop testing since the battery was getting pretty low. Now while that is on charge, I am going to play with the new Arduino that just arrived in the mail.

- Astron Boy

- Posts: 145

- Joined: Sun Mar 22, 2009 9:01 pm

- Location: Sydney, Aus

- Contact:

Re: Cottees' Sigma GN Build

Haha, 1 pin wire technology.

Hope none of your tools rust up fast!

Hope none of your tools rust up fast!

Service Manuals for Astron & Saturn powered Cars

Available manuals: TM Magna/ GH, GN Sigma/ A51-GC Galant

Available manuals: TM Magna/ GH, GN Sigma/ A51-GC Galant

Re: Cottees' Sigma GN Build

holy crap @ the tool box

-

C_Fernance

- Posts: 728

- Joined: Tue Mar 17, 2009 1:19 am

- Location: Central Coast

Re: Cottees' Sigma GN Build

My tool box looked the same a few weeks ago after some really heavy rain that caused the guttering on the rear verandah to overflow.

To make it worse it was the box i keep all my power tools in. A couple of angle grinders, drills, dremel and so on all under water. I was able to dry them out and finally got enough courage up after a couple of days to try plugging them in. Amazingly everything still works.

To make it worse it was the box i keep all my power tools in. A couple of angle grinders, drills, dremel and so on all under water. I was able to dry them out and finally got enough courage up after a couple of days to try plugging them in. Amazingly everything still works.

Re: Cottees' Sigma GN Build

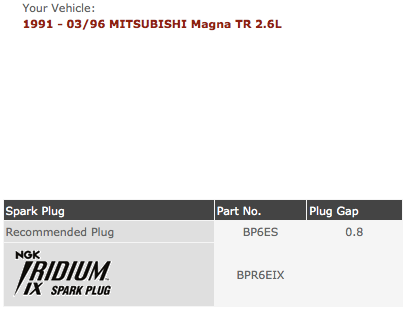

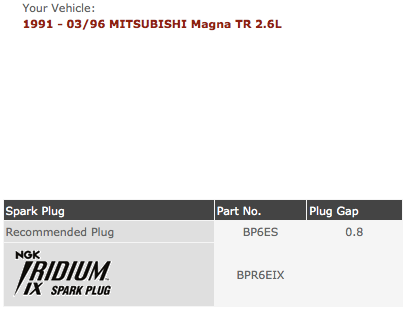

I was trying to think why the Sigma wont run constantly anymore. Then I remembered that before I changed the plugs and leads, it did run without conking out, but after it would conk out. I decided to double check the plugs. They are a little black, so I have cleaned them up and will try again. The new ones I used were NGK BP6ES which is the standard plugs for a Magna TR/TS 2.6L. The ones that came with the head, and were in the head when I first was trying to get the car running, and was running, is the NGK BPR7E. I am not sure what car they are from. I will try the new plugs again since they have been cleaned, and if there is no change, I'll try the old plugs again. Does anyone know if there is any reason why standard Magna TR plugs wouldn't work, but the non-standard ones in there would?

They both have 14mm thread diameter (B), both Projected Insulator Type (P), the original plugs have a resistor (R), the original is a colder type (7 vs 6), both have a 19mm thread length (E), and the new ones are a standard type (S). They also both have a gap of 0.8mm.

If it has been all a plug problem, I am going to do one of these in real life :

They both have 14mm thread diameter (B), both Projected Insulator Type (P), the original plugs have a resistor (R), the original is a colder type (7 vs 6), both have a 19mm thread length (E), and the new ones are a standard type (S). They also both have a gap of 0.8mm.

If it has been all a plug problem, I am going to do one of these in real life :

- Astron Boy

- Posts: 145

- Joined: Sun Mar 22, 2009 9:01 pm

- Location: Sydney, Aus

- Contact:

Re: Cottees' Sigma GN Build

I haven't messed around with my Magnas Astron motor for a while.

But that heat range and gap is just too high and narrow.

I would have thought the stock plug to be BP5ES 1.1

Plug being recomended their is more likely to be used in a VR4 Galant, and is what's recomended for my RVR...

edit: weird, for the vr4 galant it is recomending the 6es 1.1.

Maybe just gap your spark plugs to 1.1 and keep that heat range, see if it makes any difference

Sounds like you are getting an overfuelling problem if the tips were already black...

But that heat range and gap is just too high and narrow.

I would have thought the stock plug to be BP5ES 1.1

Plug being recomended their is more likely to be used in a VR4 Galant, and is what's recomended for my RVR...

edit: weird, for the vr4 galant it is recomending the 6es 1.1.

Maybe just gap your spark plugs to 1.1 and keep that heat range, see if it makes any difference

Sounds like you are getting an overfuelling problem if the tips were already black...

Service Manuals for Astron & Saturn powered Cars

Available manuals: TM Magna/ GH, GN Sigma/ A51-GC Galant

Available manuals: TM Magna/ GH, GN Sigma/ A51-GC Galant

Re: Cottees' Sigma GN Build

I checked a TR EFI with gas I have here, and that is using BP7ES and the spare Magna engine I have from a TR EFI, that is using BP6ES. In the TR/TS service and repair manual, it states that the gap should be 0.7-0.8mm, and the recommended plugs are Champion N9YC. The NGK equivalent to that is BP6ES. I'll be able to try out the new and original plugs + with different gaps and see what works.

- Astron Boy

- Posts: 145

- Joined: Sun Mar 22, 2009 9:01 pm

- Location: Sydney, Aus

- Contact:

Re: Cottees' Sigma GN Build

hmmm, weird

just doesn't sound right, but havent been mucking around with N/A for a while to remember.

Stick to what the manual says you need.

How are you leads, dizzy cap and rotor?

just doesn't sound right, but havent been mucking around with N/A for a while to remember.

Stick to what the manual says you need.

How are you leads, dizzy cap and rotor?

Service Manuals for Astron & Saturn powered Cars

Available manuals: TM Magna/ GH, GN Sigma/ A51-GC Galant

Available manuals: TM Magna/ GH, GN Sigma/ A51-GC Galant