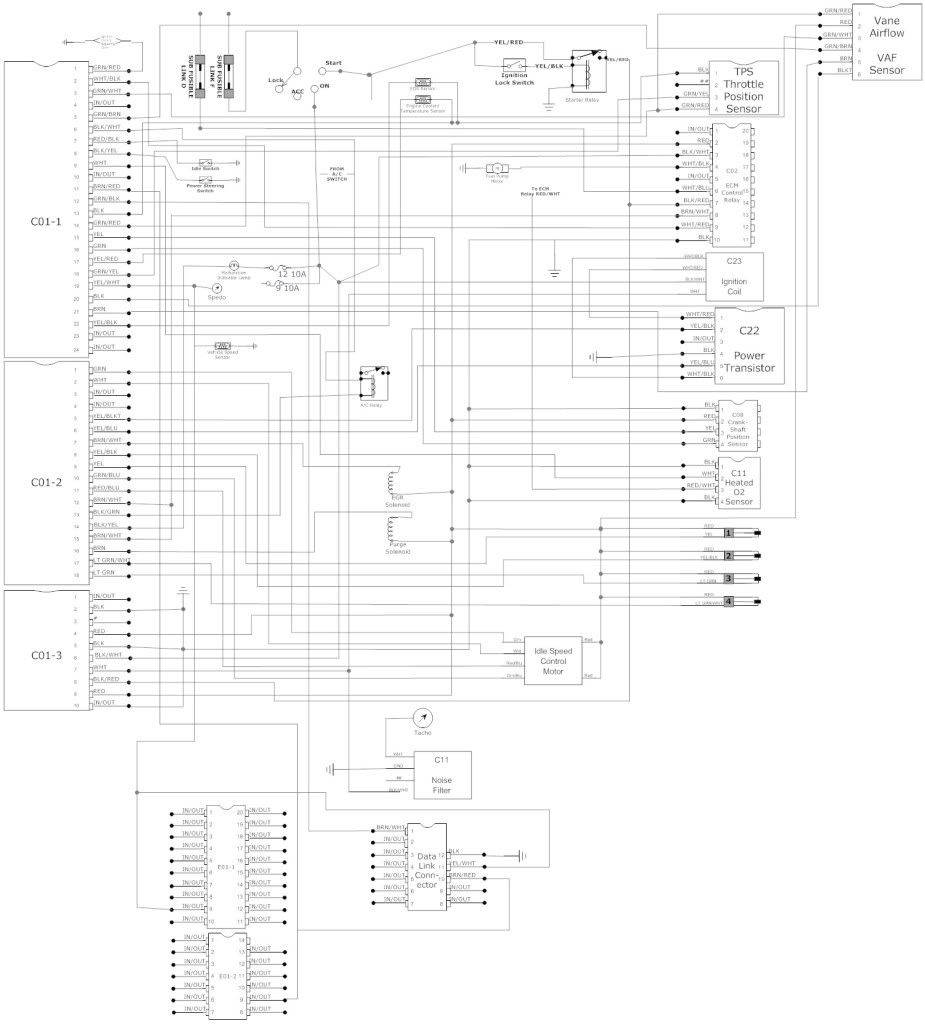

Woops, that diagram might be of use (i'm running a hyundai setup) but i did manage to get hold of an online manual that explains the circuit layout for each individual component but no whole layout in any useful sense.

In other news;

I've been relatively busy of late, there's never not anything to do with this car

First off, while I was up in the loft in the garage (yeah, I have a mezzanine in the garage

) rummaging around for something I realised that it's a good vantage point for a bird's eye shot of the engine bay. Here's a cruddy snap I shot with my phone.

A bit blurry but it's a good shot. Missing from this pic is the radiator hoses and (not that you'd really see them) the heater connections in the firewall (more on that a tad later)

Ignore the ugly S-shaped air box hose sitting in there, I was using it to reference something. It's going in the bin. but from here you can see where I've mounted the airbox, where I've moved the battery too (there's a few good reasons it's not in the boot and less wiring is one of them) which might be going in an enclosed battery box yet, just to hide the ugly looking thing.

and you can (sorta) see my half finished throttle cable mount. I may have over engineered it a little

whatever, I've got plenty of sheet left.

Now, one thing that's been keeping me up at night has been connecting the heater box. I've given up on a heater tap for now and I'm just going to bypass it when it's not needed.

I had several ideas about making a set of pipes using 5/8" refrigeration piping, which I picked up just over a metre of the soft drawn type (you can bend it with your hands) plus some elbows from reece plumbing (who'd have thought of going there for car parts

) and bending and soldering a set to carry coolant from the firewall all the way over to the heater matrix inlet only using a short length of rubber hose.

Well, that sounds like a good idea, but as usual these things never work out in practice.

It would have been way too fiddly to measure, cut, bend, solder TWO of the damned things all whilst essentially standing on my head under the dash (i hate working under the dash in

any car, let alone one this small) so I went the other direction.

I forced two lengths of hose onto the in and out's of the matrix and fed them around the heater box like so;

I did it this way because there's not enough room for both to go behind and there was no easy way to twist the hose facing into the cabin back around the heater box with out kinking it.

The hose sitting behind the box is connected to the pipe facing the firewall, and the one poking though underneath the heater tap cable clamp thingy (over the top of the box... sort of) is connected to the pipe facing the cabin of the car.

you can see what a mess the last bodgy patch up made under there. Luckily you can't really see it.... the heater box still bugs me though, you can't see it but I

KNOW that it's filthy and that's enough to make me fret over it

something else you can just see in this photo is the round silver shape at the back of the ashtray in the top of the picture. I wonder how many of you don't know that it's actually a light that illuminates the ashtray? how awesome's that!

I got it working when I originally put the car back together, but I wonder if it still works?

Anyway, back on topic...

This car originally had aircon back in the day. Dad and I tore it out many years ago, but now I'd wish we'd kept it (A/C is on the wish list considering how easy mounts and condensers etc are to get for this motor, plus the factory computer has all sorts of control over it too)

In any case, the A/C delete left two holes just above the clutch pedal on the firewall that I decided to put to use for the heater.

I made these up out of the aforementioned 5/8" fridge pipe (got the old bloke to silver solder them [pretty cool thing to watch I might add])

The short one is for the hose around the back, the long one for the hose coming over the top.

I then picked up a pair of round grommets from my mates at spectrum rubber [/sarcasm] which only needed a little modification before the whole shooting match was shoved through the holes

I (after installing them

) decided i should paint them black to make them much less noticeable. I used a good coat of black engine enamel (hi-temp, see?) but got impatient while waiting for it to dry, hence why the finish is a bit shabby. Whatever, you could only notice it because there was something shiny copper coloured sticking out under the dash. The carpet covers most of it anyway.

With the centre console back in

Anyway, I gotta bail, I have a whole post on the wiring (that I tackled myself) coming up soon!